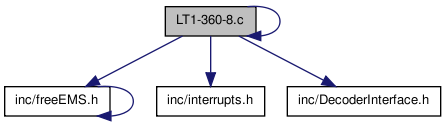

LT1-360-8.c File Reference

LT1 Optispark. More...

#include "inc/freeEMS.h"#include "inc/interrupts.h"#include "inc/DecoderInterface.h"#include "inc/LT1-360-8.h"

Go to the source code of this file.

Defines | |

| #define | LT1_360_8_C |

Functions | |

| void | LT1PTInit (void) |

| void | PrimaryRPMISR (void) |

| void | SecondaryRPMISR (void) |

| Use the rising and falling edges................... | |

| void | changeSyncStatus (unsigned char synced) |

| Change the accumulator mode to overflow every 5 inputs on PT0 making our 360 tooth wheel interrupt like a 72 tooth wheel. | |

Variables | |

| unsigned short | VCAS = 0 |

Detailed Description

LT1 Optispark.

Uses PT1 to interrupt on rising and falling events of the 8x cam sensor track. A certain number of 360x teeth will pass while PT1 is in a high or low state. Using that uniquek count we can set the positing of your Virtual CAS clock. After VCAS's position is set set PT7 to only interrupt on every 5th tooth, lowering the amount of interrupts generated, to a reasonable level.

- Note:

- Pseudo code that does not compile with zero warnings and errors MUST be commented out.

- Todo:

TODO This file contains SFA but Sean Keys is going to fill it up with

TODO wonderful goodness very soon ;-)

Definition in file LT1-360-8.c.

Define Documentation

| #define LT1_360_8_C |

Definition at line 48 of file LT1-360-8.c.

Function Documentation

| void changeSyncStatus | ( | unsigned char | synced | ) |

Change the accumulator mode to overflow every 5 inputs on PT0 making our 360 tooth wheel interrupt like a 72 tooth wheel.

PT0 Accumulator Mode

- Todo:

- TODO Decide if an explicit parameter is necessary if not use a existing status var instead for now it's explicit.

- Todo:

- TODO the register below does not exist and I couldn't figure out what you meant to do...

Definition at line 216 of file LT1-360-8.c.

References PACN0, PACTL, TCTL1, and TIOS.

Referenced by SecondaryRPMISR().

00216 { 00217 if (synced != 1) { /* disable accumulator counter, so an ISR is fired on all 360 teeth */ 00218 PACTL = 0x00; /* disable PAEN and PBOIV */ 00219 /* (PACTL) 7 6 5 4 3 2 1 0 00220 PAEN PAMOD PEDGE CLK1 CLK0 PAOVI PAI */ 00221 }else{ /* enable accumulator so an ISR is only fired on every "5th tooth of the 360x track" */ 00222 // TIOS = TIOS & "0xCC0x83" WTF!?LOL!! 0x80; /* PT7 input */ 00223 // TCTL1 = TCTL1 & "0xCC0x83" WTF!?LOL!! 0xC0; /* Disconnect IC/OC logic from PT7 */ 00224 TIOS = TIOS & 0x80; /* PT7 input */ 00225 TCTL1 = TCTL1 & 0xC0; /* Disconnect IC/OC logic from PT7 */ 00227 PACN0 = 0xFB ; /* Calculation, $00 – $05 = $FB. This will overflow in 5 more edges. */ 00228 PACTL = 0x52; /* Enable PA in count mode, rising edge and interrupt on overflow 01010010 */ 00229 } 00230 }

| void LT1PTInit | ( | void | ) |

Setup PT Capturing so that we can decode the LT1 pattern

- Todo:

- TODO Put this in the correct place

Definition at line 61 of file LT1-360-8.c.

| void PrimaryRPMISR | ( | void | ) |

Primary RPM ISR

- Todo:

- TODO Docs here!

- Todo:

- TODO possibly add code to make sure we are in divide mode, if not error out

- Todo:

- TODO fill in or remove the else

Definition at line 72 of file LT1-360-8.c.

References isSynced, PORTJ, PrimaryTeethDuringHigh, PrimaryTeethDuringLow, PTIT, TFLG, and VCAS.

00072 { 00073 /* Clear the interrupt flag for this input compare channel */ 00074 TFLG = 0x01; 00075 00076 /* Save all relevant available data here */ 00077 // unsigned short codeStartTimeStamp = TCNT; /* Save the current timer count */ 00078 // unsigned short edgeTimeStamp = TC0; /* Save the edge time stamp */ 00079 unsigned char PTITCurrentState = PTIT; /* Save the values on port T regardless of the state of DDRT */ 00080 // unsigned short PORTS_BACurrentState = PORTS_BA; /* Save ignition output state */ 00081 00082 // unsigned char risingEdge; /* in LT1s case risingEdge means signal is high */ 00083 // if(fixedConfigs1.coreSettingsA & PRIMARY_POLARITY){ 00084 // risingEdge = PTITCurrentState & 0x01; 00085 // }else{ 00086 // risingEdge = !(PTITCurrentState & 0x01); 00087 // } 00088 00089 PORTJ |= 0x80; /* Echo input condition on J7 */ 00090 if(!isSynced){ /* If the CAS is not in sync get window counts so SecondaryRPMISR can set position */ 00091 if (PTITCurrentState & 0x02){ 00092 PrimaryTeethDuringHigh++; /* if low resolution signal is high count number of pulses */ 00093 }else{ 00094 PrimaryTeethDuringLow++; /* if low resolution signal is low count number of pulses */ 00095 } 00096 }else{ /* The CAS is synced and we need to update our 360/5=72 tooth wheel */ 00098 VCAS = VCAS + 10; /* Check/correct for 10deg of CAM movement */ 00100 } 00101 }

| void SecondaryRPMISR | ( | void | ) |

Use the rising and falling edges...................

Secondary RPM ISR

- Todo:

TODO Docs here!

TODO Add a check for 1 skip pulse of the 8x track, to prevent possible incorrect sync.

TODO Possibly make virtual CAS 16-bit so was can get rid of floating points and use for syncing

- Todo:

- TODO fill in or remove the else

Definition at line 110 of file LT1-360-8.c.

References changeSyncStatus(), fixedConfig1::coreSettingsA, Counters, Counter::crankSyncLosses, fixedConfigs1, isSynced, PORTJ, PRIMARY_POLARITY, PrimaryTeethDuringHigh, PrimaryTeethDuringLow, PTIT, TFLG, and VCAS.

00110 { 00111 /* Clear the interrupt flag for this input compare channel */ 00112 TFLG = 0x02; 00113 00114 /* Save all relevant available data here */ 00115 // unsigned short codeStartTimeStamp = TCNT; /* Save the current timer count */ 00116 // unsigned short edgeTimeStamp = TC1; /* Save the timestamp */ 00117 unsigned char PTITCurrentState = PTIT; /* Save the values on port T regardless of the state of DDRT */ 00118 // unsigned short PORTS_BACurrentState = PORTS_BA; /* Save ignition output state */ 00119 unsigned char risingEdge; 00120 if(fixedConfigs1.coreSettingsA & PRIMARY_POLARITY){ 00121 risingEdge = PTITCurrentState & 0x01; 00122 }else{ 00123 risingEdge = !(PTITCurrentState & 0x01); 00124 } 00125 PORTJ |= 0x40; /* echo input condition */ 00126 00127 if (!isSynced & risingEdge){ /* If the CAS is not in sync get window counts and set virtual CAS position */ 00128 /* if signal is high that means we can count the lows */ 00129 switch (PrimaryTeethDuringLow){ 00130 case 23: /* wheel is at 0 deg TDC #1, set our virtual CAS to tooth 0 of 720 */ 00131 { 00132 VCAS = 0 ; 00133 changeSyncStatus((unsigned char) 1); 00134 break; 00135 } 00136 case 38: /* wheel is at 90 deg TDC #4, set our virtual CAS to tooth 180 of 720 */ 00137 { 00138 VCAS = 180; 00139 changeSyncStatus((unsigned char) 1); 00140 break; 00141 } 00142 case 33: /* wheel is at 180 deg TDC #6 set our virtual CAS to tooth 360 of 720 */ 00143 { 00144 VCAS = 360; 00145 changeSyncStatus((unsigned char) 1); 00146 break; 00147 } 00148 case 28: /* wheel is at 270 deg TDC #7 set our virtual CAS to tooth 540 of 720 */ 00149 { 00150 VCAS = 540; 00151 changeSyncStatus((unsigned char) 1); 00152 break; 00153 } 00154 default : 00155 { 00156 Counters.crankSyncLosses++; /* use crankSyncLosses variable to store number of invalid count cases while attempting to sync*/ 00157 break; 00158 } 00159 PrimaryTeethDuringLow = 0; /* In any case reset counter */ 00160 } 00161 } 00162 if(!isSynced & !risingEdge){/* if the signal is low that means we can count the highs */ 00163 switch (PrimaryTeethDuringHigh){ /* will need to additional code to off-set the initialization of PACNT since they are not 00164 evenly divisible by 5 */ 00165 case 7: /* wheel is at 52 deg, 7 deg ATDC #8 set our virtual CAS to tooth 104 of 720 */ 00166 { 00167 00168 break; 00169 } 00170 case 12: /* wheel is at 147 deg, 12 deg ATDC #3 set our virtual CAS to tooth 294 of 720 */ 00171 { 00172 00173 break; 00174 } 00175 case 17: /* wheel is at 242 deg, 17 deg ATDC #5 set our virtual CAS to tooth 484 of 720 */ 00176 { 00177 00178 break; 00179 } 00180 case 22: /* wheel is at 337 deg, 22 deg ATDC #2 set our virtual CAS to tooth 674 of 720 */ 00181 { 00182 00183 break; 00184 } 00185 default : 00186 { 00187 Counters.crankSyncLosses++; /* use crankSyncLosses variable to store number of invalid/default count cases while attempting to sync*/ 00188 break; 00189 } 00190 00191 } 00192 PrimaryTeethDuringHigh = 0; /* In any case reset counter */ 00193 } 00194 if(isSynced & risingEdge){ /* We are in sync and need to make sure our counts are good */ 00195 00196 /* System is synced so use adjusted count numbers to check sync */ 00198 } 00199 }

Variable Documentation

| unsigned short VCAS = 0 |

Definition at line 55 of file LT1-360-8.c.

Referenced by PrimaryRPMISR(), and SecondaryRPMISR().

1.6.3

1.6.3